BLOGS

NPT vs BSPT Threads: Key Differences, Compatibility, and Applications

1. Introduction

Pipe threads might seem like a mundane detail in plumbing and industrial systems, but their role is absolutely critical. Among the most common standards worldwide are NPT (National Pipe Taper) and BSPT (British Standard Pipe Taper) threads. Despite serving similar functions, these threads differ in subtle yet vital ways. Choosing the wrong thread type can lead to leaks, mechanical failure, or costly downtime.

Expert Insight:

“Selecting the correct pipe thread standard is fundamental to ensuring system integrity and preventing leaks.” - John Smith, Senior Pipeline Engineer

This article unpacks the differences between NPT and BSPT threads, explores their compatibility, and offers practical advice for selecting the right thread for your needs.

2.What Are Pipe Threads?

Pipe threads are helical ridges cut into pipes and fittings, enabling components to screw together securely. But it’s not just about joining parts; the thread’s geometry-its angle, pitch, and taper-directly impacts sealing performance.

○ Thread Angle: The angle between the flanks of the thread.

○ Pitch: Threads per inch (TPI), indicating thread density.

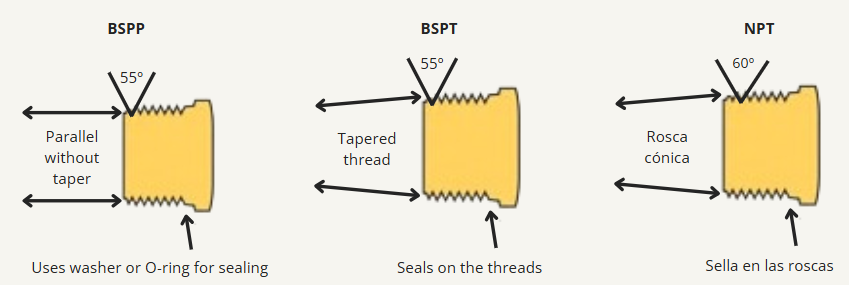

○ Taper vs Parallel: Tapered threads narrow along the length; parallel threads maintain a constant diameter.

○ Nominal Pipe Size (NPS): A standardized pipe size that often differs from the actual thread diameter.

3.What is NPT thread?

NPT threads are the American standard, defined by ANSI/ASME B1.20.1.

Thread Angle: 60°

Thread Form: Both male and female threads are tapered at a rate of 1:16 (diameter reduces by 1 unit every 16 units lengthwise).

Sealing: Achieved by the wedging action of tapered threads, but sealants like PTFE tape are commonly used to ensure leak-tightness.

Thread Pitch: For example, 1/2" NPT typically has 14 threads per inch.

Applications: Predominantly used in North America for gas, water, and oil pipelines.

4.What is BSP Threads?

BSP threads, standardized under ISO 7-1 and BS 21, are prevalent in Europe, the UK, Australia, and many Commonwealth countries.

○ Types:

- BSPT (Tapered): Male threads tapered; female threads tapered or parallel.

- BSPP (Parallel): Both male and female threads are parallel.

○ Thread Angle: 55° Whitworth profile with rounded crests and roots.

○ Sealing: BSPT relies on metal-to-metal sealing via taper; BSPP requires O-rings or gaskets.

○ Thread Pitch: 11 threads per inch for 1/2" BSPT.

○ Applications: Water, gas, and steam fittings in Europe and Commonwealth countries.

5.NPTvs BSPT:Side-by-Side Comparison

|

NPT vs BSPT |

||

|

Feature |

NPT |

BSPT |

|

Thread Angle |

60° |

55° |

|

Thread Profile |

Sharp crests and roots |

Rounded crests and roots |

|

Thread Form |

Tapered(male &female) |

Tapered male;female tapered or parallel |

|

Taper Rate |

1:16 |

1:16 |

|

Thread Pitch(1/2”) |

14 TPI |

11 TPI |

|

Sealing Method |

Tapered thread interference +sealant |

Metal-to-metal taper seal,sometimes sealant |

|

Common Regions |

North America |

Europe,UK,Australia |

|

Compatibility |

Only with NPT threads |

Compatible with BSPP female threads |

Key Notes:

NPT threads have a steeper 60° angle, making them incompatible with BSP threads.

BSPT threads have a Whitworth 55° thread form with rounded crests and roots.

Mixing NPT and BSP threads can cause leaks and mechanical failure due to mismatched thread angles and pitches.

6. BSPP (G) Threads: Parallel Pipe Threads

BSPP threads, also known as G threads, are parallel threads with a 55° Whitworth thread angle.

Thread Form: Parallel (constant diameter).

Sealing: Requires an O-ring, gasket, or sealant to achieve a leak-proof joint.

Applications: Common in hydraulic, pneumatic, and instrumentation connections where a seal is achieved via a sealing element rather than thread interference.

Standards: ISO 228-1.

7. How do l know if I have NPT Or BSPT?

○ Use a thread pitch gauge to count TPI.

○ Employ a profile gauge to measure thread angle (60° vs 55°).

○ Visually inspect: NPT threads appear sharper and tapered; BSP threads are rounder and may be parallel or tapered.

○ Measure diameter at multiple points to determine taper.

8.Compatibility and Conversion

○ NPT and BSPT are not interchangeable.

○ BSPT male threads can sometimes fit BSPP female threads with proper sealing.

○ Use adapters when connecting incompatible threads.

○ Always apply appropriate sealants and follow installation guidelines.

9.Practical Applications and Selection Tips

○ Use NPT in North America or with American-standard equipment.

○ Choose BSPT/BSPP for European, UK, or Commonwealth applications.

○ For high-pressure hydraulics, BSPP with O-ring seals is preferred.

○ Always verify thread type before installation.

10.Conclusion

NPT and BSPT threads may look similar, but their differences in angle, pitch, and sealing methods are significant. Proper thread selection ensures leak-free, durable connections and system safety. Armed with this knowledge, you can confidently specify the right thread for your project.

Appendix: Quick Reference Table

|

Size (inches) |

NPT TPI |

BSPT TPI |

BSPP TPI |

|

1/8" |

27 |

28 |

28 |

|

1/4" |

18 |

19 |

19 |

|

3/8" |

18 |

19 |

19 |

|

1/2" |

14 |

11 |

11 |

|

3/4" |

14 |

14 |

14 |