BLOGS

Understanding Single-Stage vs. Two-Stage Pressure Regulators

When working with gases, controlling pressure accurately and reliably is crucial. Pressure regulators ensure safe and consistent gas delivery by reducing high-pressure gas to a usable lower pressure. Two common types of regulators are single-stage and two-stage pressure regulators. Each has distinct features, advantages, and ideal applications. Let’s explore their definitions, working principles, and how to choose the right one for your needs.

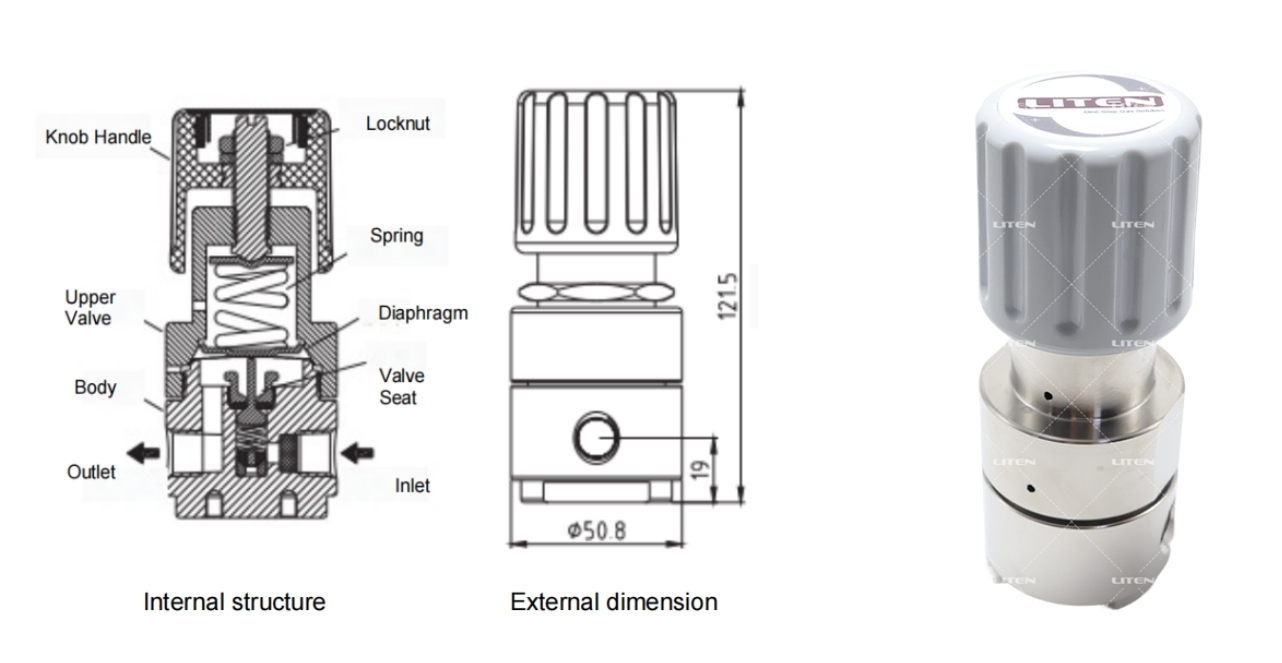

What Is a Single-Stage Pressure Regulator?

A single-stage pressure regulator reduces high-pressure gas to a set lower pressure in one step. It uses a spring-loaded valve mechanism that balances the force of the incoming gas pressure against a spring to control the outlet pressure.

How it works:

• High-pressure gas enters the regulator.

• The gas pressure pushes against a diaphragm or piston.

• This pressure compresses a spring, opening or closing the valve to maintain the set outlet pressure.

• When the outlet pressure reaches the set value, the valve closes to prevent further pressure increase.

Advantages:

• Simple design and easy to use.

• Lower cost compared to two-stage regulators.

• Suitable for applications where precise pressure control is not critical.

• Typical uses: Basic gas cylinders, welding and cutting, gas filling, and other general-purpose applications where minor pressure fluctuations are acceptable.

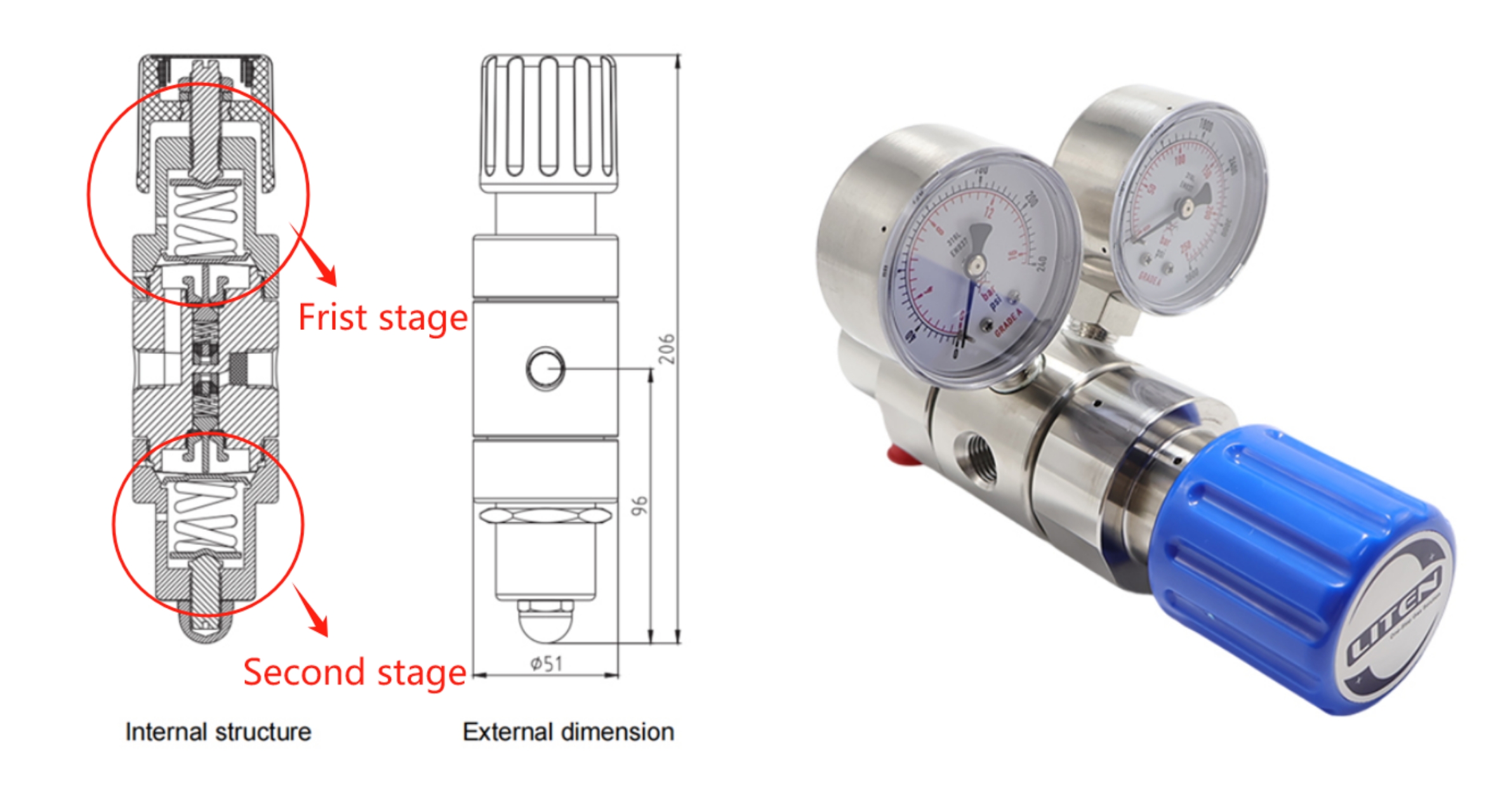

What Is a Two-Stage Pressure Regulator?

A two-stage pressure regulator reduces gas pressure in two sequential steps for better control and stability.

How it works:

• The first stage lowers the high inlet pressure to an intermediate pressure.

• The gas then flows to the second stage, which further reduces the pressure to the desired outlet level.

• Each stage has its own diaphragm and spring mechanism, working independently to maintain stable pressure.

Advantages:

• Provides much more stable and consistent outlet pressure.

• Minimizes pressure fluctuations even as the gas cylinder empties.

• Ideal for applications requiring high precision and stability.

• Typical uses: Laboratories, industrial automation, medical equipment, and other settings where pressure consistency is critical.

Single-Stage vs. Two-Stage Regulators: Key Differences

|

Feature |

Single-Stage Regulator |

Two-Stage Regulator |

|

Pressure Control |

Reduces pressure in one step; less stable output |

Two-step reduction; highly stable output |

|

Precision |

Lower precision; output pressure may fluctuate |

High precision; maintains constant pressure |

|

Complexity |

Simple design |

More complex with two independent stages |

|

Cost |

More affordable |

Higher upfront cost |

|

Typical Applications |

General use, welding, gas cylinders |

Critical applications like labs, medical devices |

How to Choose the Right Regulator?

Choose a single-stage regulator if:

○ You need a cost-effective, simple solution.

○ Your application can tolerate some pressure variation.

○ You use gas intermittently or for less sensitive tasks.

Choose a two-stage regulator if:

○ You require precise, stable pressure control.

○ Your process is sensitive to pressure fluctuations.

○ You operate in environments where consistent gas delivery is critical.

Summary

Both single-stage and two-stage pressure regulators serve important roles in gas pressure management. Single-stage regulators offer simplicity and affordability for general use, while two-stage regulators provide superior precision and stability for demanding applications. Understanding your specific pressure control needs will help you select the best regulator for your situation.