LITEN VCR Pressure Gauge 63mm | ASME Certified High Purity Instrument for Semiconductor & Pharma

LITEN 63mm High Purity VCR Pressure Gauge

Industrial-Grade Precision Measurement

LITEN's 63mm VCR pressure gauge delivers laboratory-grade accuracy (±1.6% full scale) for critical process control applications. Engineered with ultra-clean 316L stainless steel components, our gauges meet stringent requirements for semiconductor manufacturing, pharmaceutical processes, and high-purity gas systems.

Key Advantages

✅ Certified Reliability

ASME B40.1 Grade A Certified | Cleanroom assembled | RoHS compliant

✅ Ultraclean Surface Finish

Optional <0.25μm Ra polishing (standard <1.6μm Ra)

FDA-compliant surface treatment for contamination-sensitive environments

✅ Advanced Cleaning Protocol

Ultrasonic-cleaned components

Passivated surfaces per ASTM A967

Particle-free packaging

Technical Specifications

Parameter

Specification

Accuracy

±1.6% of full scale

Pressure Ranges

0-3000 PSI, Vac-15 PSI, Vac-300 PSI, 0-60 PSI

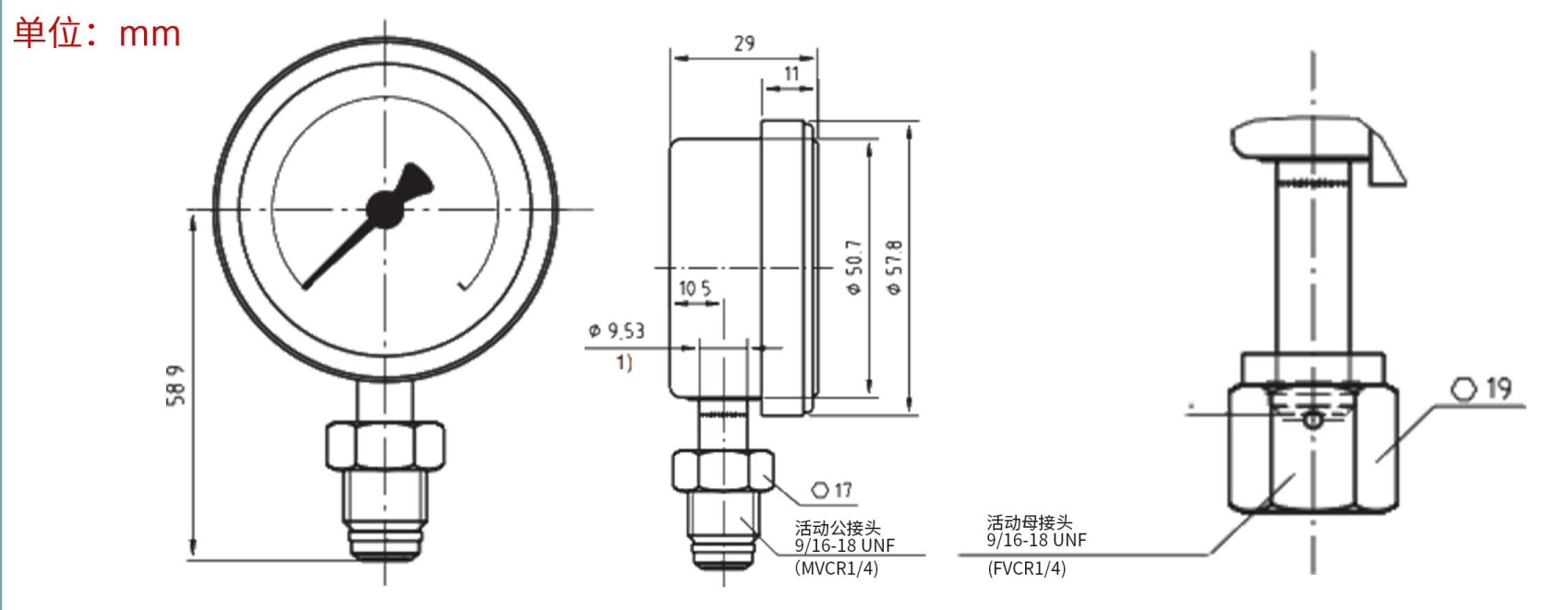

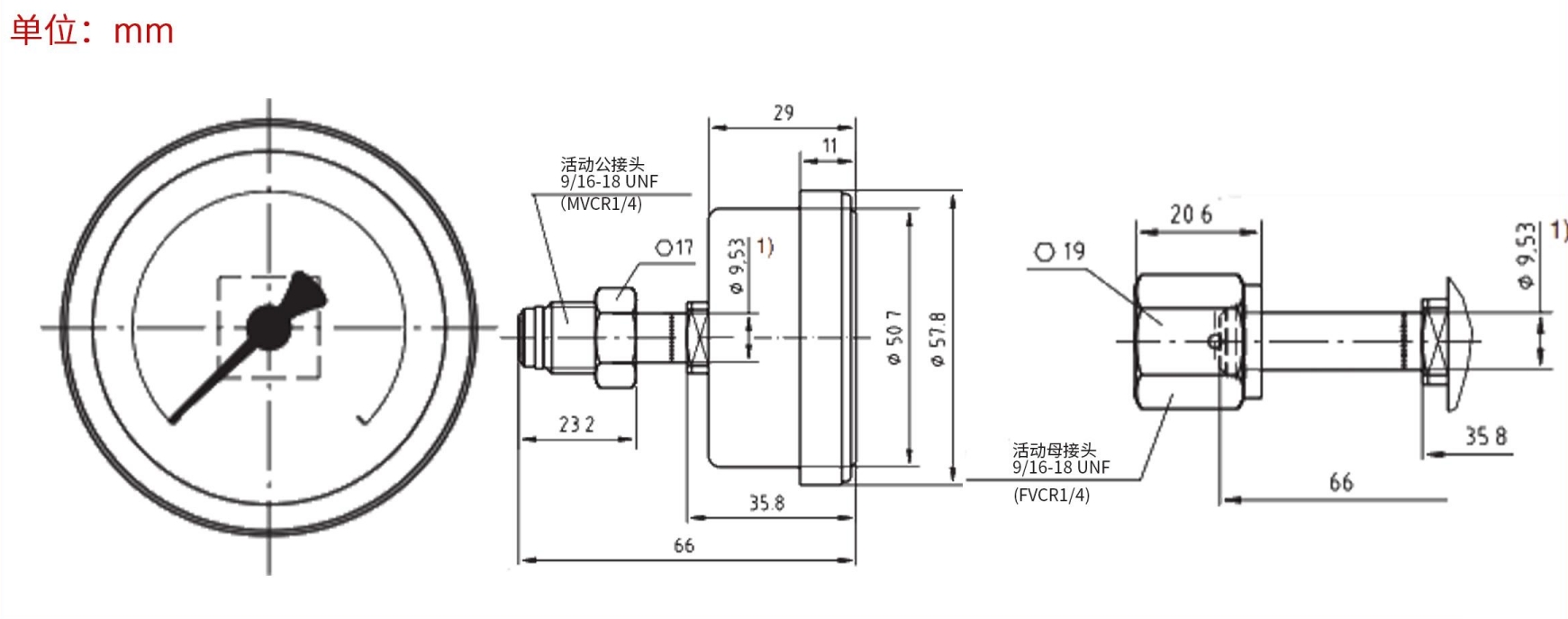

Connection Types

G ¼ B Male, R ¼ Male, ¼ NPT Male, 9⁄16-18 UNF Male (¼ VCR® compatible)

Materials

316L SS Bourdon tube

Process Connection

Lower/Lower back configuration

Temperature Range

-20°C to +60°C (operating)

Stainless steel housing

Safety glass window

Industry Applications

Semiconductor Manufacturing

Ideal for CVD/ALD equipment gas lines

Compatible with NF3, ClF3 and other aggressive media

Pharmaceutical Systems

Validatable for SIP/CIP processes

Electropolished surfaces meet FDA 21 CFR requirements

High Purity Gas Delivery

Helium leak tested <1x10-9 mbar·l/s

Ultra-low outgassing surfaces